Below: While the neck is clamped securely in place, the neck itself is used as a template guide, and at this point we stick the template physically to the body using double-sided tape. The tape being used is carpet tape. 3M brand carpet tape is recommended, but if that particular brand is not available where you are, use whatever is available at your local hardware store. To note: 3M is specifically recommended due to the fact it leaves the least residue when removing it.

Below: Template is applied, and the neck has been removed… but we’re not done yet.

Below: The template is literally banged into place using a mallet to make absolutely sure the template is adhered properly and will not move.

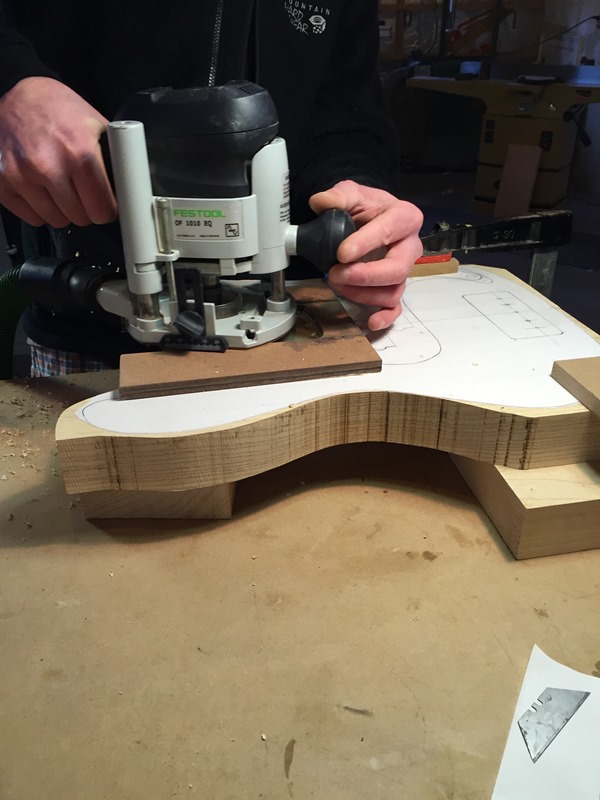

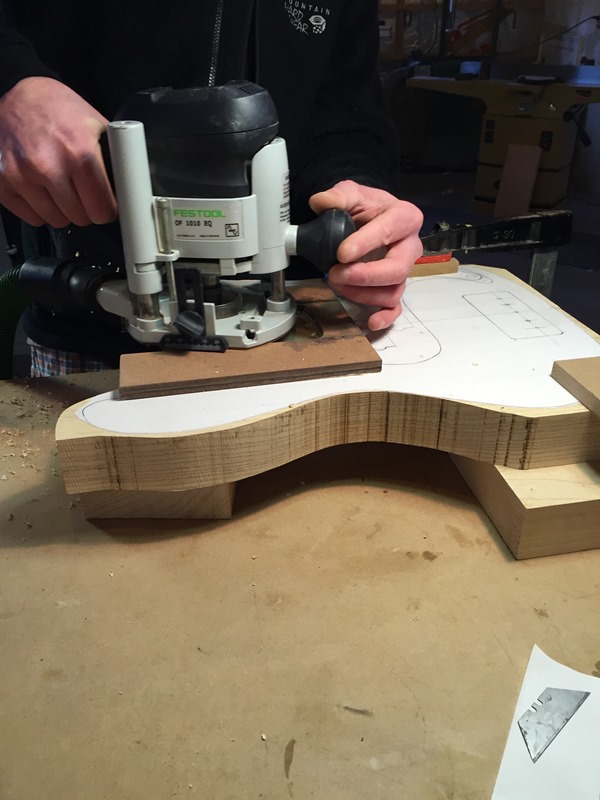

Below: The routing is started with 1/4-inch cutter head bearing top bit.

The bit in particular used is the CMT 801.128.11B mortising bit seen here: https://www.amazon.com/dp/B001FD7K86

Note: The entire route for this particular build was able to be completed with just this one bit, as the entire depth of the pocket was only 5/8th-inch deep. This may not be your experience, and you may need to use multiple router bits to achieve your final depth.

Below: After routing, the neck is then fitted into the pocket. Since the template was sized correctly, adjustments did not need to be made and the neck fit correctly. The fit was very snug, as it should be.

IMPORTANT NOTE: If a spray finish is to be applied to the neck, do not overfit (i.e. too tight) the neck, as the finish itself will add some thickness.

Next up: Fabricating the control cavity routing template.

Where are the rest of the build steps?

You can view them all here.

yeah, but how does one make a template for a round-butt neck? you kind a left that critical part out.